Additive manufacturing is taking more and more space in the transportation sector and many people are even talking about fully 3D printed cars coming out in near future. We are well aware that how automotive industry is capitalizing 3D printing technology to manufacture various car components.

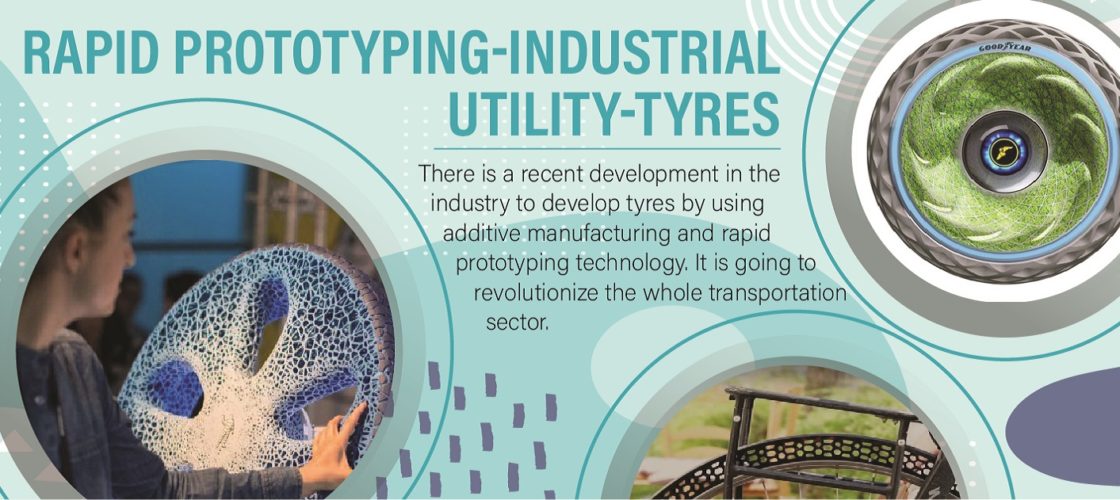

There is a recent development in the industry to develop tyres by using additive manufacturing and rapid prototyping technology. It is going to revolutionize the whole transportation sector.

Here are some of the main benefits of 3D printing for car tires:

Optimizing the Products:

3D printing is offering new possibilities regarding the designs and it is really useful to develop new concepts of tires. A designer gets lots of freedom when it comes to manufacturing using the 3D printing technology. Digital manufacturing is a great way to rethink the design of tires, in order to improve their capacities, and also their impact on the planet.

Mass-Customization:

3D printing enables mass-customization, as it is really easy to make many iterations on the same product and to adapt it to individual customer needs.

Reducing Material Waste:

Additive manufacturing is an eco-friendly process and reduces material waste substantially compared to conventional processes. As while 3D printing a product, you only have to use the precise amount of material that you need to create it.

Saves Money:

3D printing is a cost saving method to prototype which reduces your product development budget. As to create your different iterations, you will just have to modify your 3D model software design and print it again. You can further save money by using less costly material to print your prototype.

Some Innovative 3D Printing Tyre Projects:

Michelin, 3D Printed Biodegradable Airless Tires:

French multinational tyre manufacturer Michelin has recently unveil its new tire concept, the Vision, an airless, spongelike 3D-printed dream that Michelin claimed is “within reach.”

Said to be inspired by nature, the Vision blends wheel and tire functions into one unit. It looks like a combination of fire coral, a sand dollar, neurons, and a Scotch-Brite scrubber, but that look is not just a look. It all feeds into the concept’s multi-functionality.

The project started with the aim to eliminate one of the biggest consumer tire issues: the need to maintain proper air pressure. Without air, it is avoiding some traditional tire problems that we know, like low pressure, deflation or blowouts, and also safety problems.

3DPrinted Airless Bicycle Tyres:

BigRep 3D printed airless tire replaces ‘air’ as a necessity in the tire by customizing the pattern to be one of a three-layered honeycomb design. Based on the same principle, the design can be altered to fit the requirements of specific types of biking, such as mountain biking and road racing, or for different weather and speed conditions.

The main advantage of airless tires as opposed to our average run-of-the-mill tires is that they simply never go flat. Since the release of the airless bicycle tire video, it has received coverage from around the globe, such as on online news sites Inhabitat and CNET.

Once a luxury, airless tires are now looking to become standard practice in the transportation world.

Goodyear’s 3D Printed Tyres:

First presented at the 2018 Geneva International Motor Show, the Goodyear’s Oxygene tire is devised to stimulate conversations about how the automotive industry can provide cleaner solutions for people and the environment.

In Goodyear’s proposal document, Oxygene is made from a rubber powder, recycled from disused tires. It is printed by a conceptual selective laser sintering (SLS) process, and assembled by robotic arms. Inlets in the tire are designed to contain moss that absorbs moisture from the road through the tread, and releases fresh oxygen through photosynthesis.

Goodyear explains the potential impact the tires could have; “In a city similar in size to greater Paris with about 2.5 million vehicles, this would mean generating nearly 3,000 tons of oxygen and absorbing more than 4,000 tons of carbon dioxide per year.”