The jewelry industry has traditionally been craft-based, with automation mainly restricted to various individual stages of jewelry manufacturing. Jewelry design and model making are very time-consuming tasks, which require unique skills difficult to master.

Rapid Prototyping (RP) technology in jewelry design and manufacture offers a significant breakthrough for the industry. It allows designers to simplify the iterative design and to easily modify the details of the sketches to facilitate sketching of jewelry products in any shape and sizes, thus shortening the time require to make final models.

Professional jewelry designers who are specialized in RP technology are making accurate hard copies of created CAD models. These technologies are facilitating every details of the jewelry model highly visible from every angle.

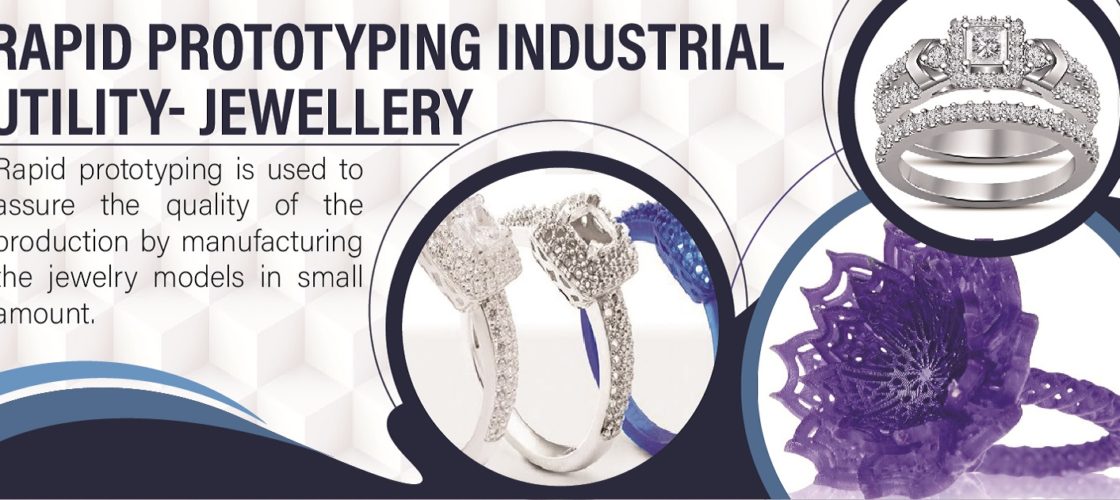

Furthermore, RP is used to assure the quality of the production by manufacturing the jewelry models in small amount. That is an excellent way to control and improve quality as well as to create more complex jewelry models.

Advantages:

Some of the advantages of using RP technology for jewellery design are as follows:

1. It allows seeing and feeling the product before the launch of expensive jewelry models.

2. It allows designers to simplify the iterative design, to modify the details of the sketches, to facilitate sketching of jewelry products in any shapes and sizes, and to shorten the required time for go to making models.

3. It is giving us possibility of early presentation of jewelry models to the customer at initial stage of buying process.

4. It allows start-ups to exclude engineering and design errors, which are sometimes difficult to see on a computer screen. Modern technology allows producing prototypes of products from different materials.

5. High print accuracy and excellent quality of the printed jewellery.

6. Another advantage is that the prototype can be made from virtually any material with all of its properties. The most popular is considered 3D prototyping of ABS (ABS) plastic.