The advent of Rapid Prototyping (RP) and 3D printing technology has transformed the landscape of medical industry and has opened many new applications areas.

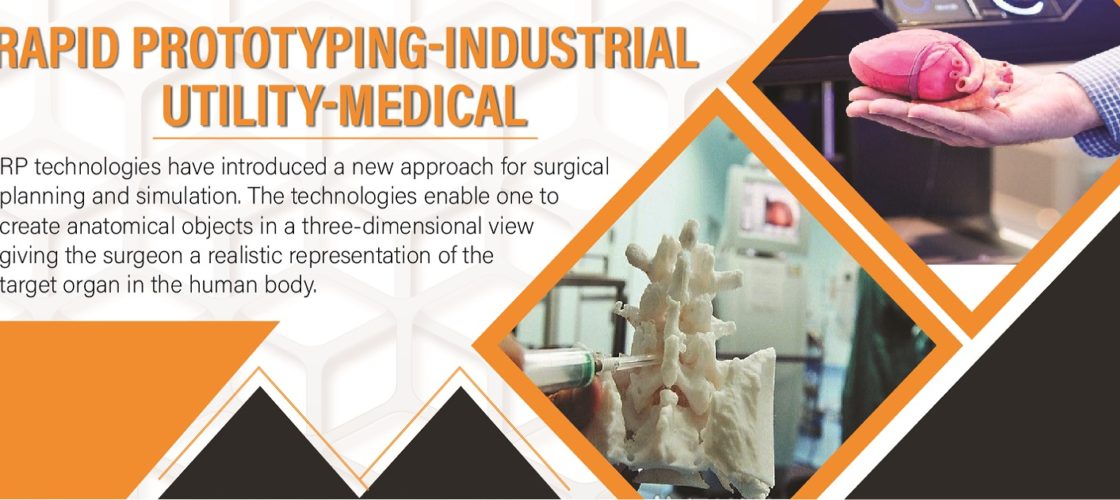

RP technologies have introduced a new approach for surgical planning and simulation. The technologies enable one to create anatomical objects in a three-dimensional view giving the surgeon a realistic representation of the target organ in the human body.

Some of the other important applications of rapid prototyping in medical industry are as follows:

Developments of Medical Devices and Instrumentations:

Medical instruments that have been upgraded using the 3D printing technology include surgical fasteners, scalpels, retractors, display systems, among many others.

Besides designing these medical devices, the prototyping technology is also used in manufacturing devices that need to be specifically customized for a particular patient.

Most hearing aid devices are designed using the stereolithography or the selective laser sintering.

Other area that is adapting the rapid prototyping technology is the replacement of teeth.

Application in the Manufacture of Prostheses and Implants:

Rapid prototyping plays a crucial role when it comes to implantations and use of prostheses. With the help of this technology, prostheses that have been specifically designed for a particular patient are now available. Patients whose requirement is outside the standard size or those who require special treatments can now get some customized prostheses that fit them at an affordable cost.

Rapid prototyping and computed tomography technologies utilize techniques, such as X-rays and NMRI, and enable the transfer of data generated to be used as the input data for the rapid prototyping process.

CT scan used in the hip replacement surgical procedure. Data received from the CT scan is combined with engineering data to join to the bone. The data thus obtained is then turned into a plastic model to be applied as an implant for the patient.

Other medical application of the prototyping technologies is in the replacement of the external missing organs. In such instances, the remaining organ is scanned into a three-dimensional image, and the mirror-image of the data acquired is used to build data for the missing organ.

Planning for Surgical Procedures and Other Related Applications:

Models of complex organs in the body are being developed by using the rapid prototyping techniques. The models are used by surgeons to get the real impression of the structures before a surgical intervention is performed.

Complex procedures, especially those ones involving the craniofacial and the maxillofacial surgeries utilize the scientific application. The models are always placed in the surgical rooms where the procedure is being done by the surgeon.

The most commonly used technology for this application is the stereolithography. The model has some of the most interesting features, such as the transparency and developments in the color resins, enable a clear differentiation of tumors and any other foreign growth in the bodies.

Rapid prototyping technology is also used in the manufacture of biologically active implants and also in tissue engineering. The application involves the use of selective laser sintering of ceramics.

Improved quality – of existing medical products, devices, parts, equipment, etc. can be improved in quality for example, being stronger, lighter versions etc.

Patient specific models – the development of patient specific parts, e.g. prosthetics, dental products, etc.

Reduced time to market – is extensively used to reduce the time taken for products to reach the market.

Training aids – prototypes/models can be developed to:

practice complex operations on models, rather than “test” on live patients (realistic effects such as blood type substances for specific cuts can be added)

aid the training of new medical staff

for educating patients as to treatment they will be undertaking

Alternative doses – rather than offer one size fits all, specific dose size (for tablets) could be produced, which slightly vary to a patient’s needs (this is especially applicable to children, where their size differs greatly)

User trials – conduct user trials through offering different versions of medical products, which are quickly 3D printed and see which ones perform best.